Lightboxes are extremely popular. Their price range is in the middle between advertising billboards and channel letters. They are used everywhere – both inside and outside of buildings.

As the name suggests, it is illuminated advertising. Light in advertising has many advantages – it allows to obtain not only aesthetic effects of advertising, but also to ensure its visibility in the dark. This is particularly important during the winter, when the main vehicular and pedestrian traffic is moving in the dark to and from work. Light can also ensure greater visibility of advertising, attracting attention with its brightness, colours or blinking.

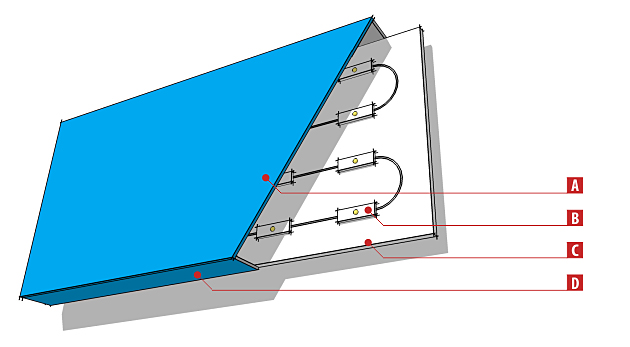

The main components of the lightboxes:

A. Frontal plane

B. Light source

C. Backside / base

D. Side edge

The most popular light sources currently used in advertising are light emitting diodes (LEDs). They have so many advantages that they easily compete with other light sources, although this technology has not yet achieved its full potential and limits, and is constantly improved. Read more about LED technology in section Technologies.

Older versions of advertisements still have fluorescent lamps. Neon lights are also used although their fragility and susceptibility to cold reduces the attractiveness.

Lightbox housing can be made of a wide range of materials – plastics (PVC or acrylic glass), aluminium, aluminium composite panels, sheets, and metal structures in case of large advertising. The shape of lightboxes ranges from rectangular, oval or anything customised (e.g. reiterating the logo). Production of the latter by its complexity is comparable to the production of channel letters.

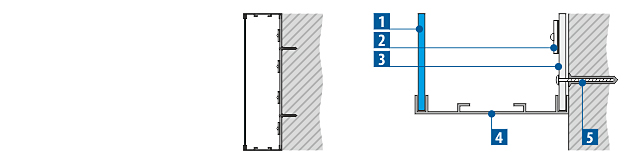

Lightbox with aluminium profile 140 mm or 200 mm. Illuminated only in front

1. Light distributing 3-4 mm acrylic panel

2. Light source

3. PVC panel or metal sheet

4. Aluminium profile:

140 mm – one-sided

200 mm – double-sided lightboxes

5. Screws (~4×70 mm)

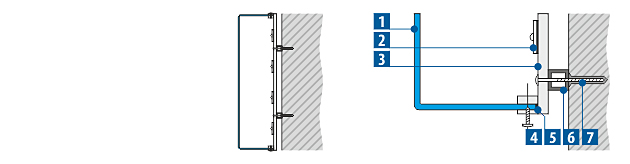

Bent acrylic front panel. Illuminated front and sides

1. Light distributing 3-4 mm acrylic panel

2. Light source

3. PVC base plate (10 mm)

4. Front panel mounting screws

5. Sealing gaskets

6. Metal profile (20×20)

7. Screws (~4×70 mm)

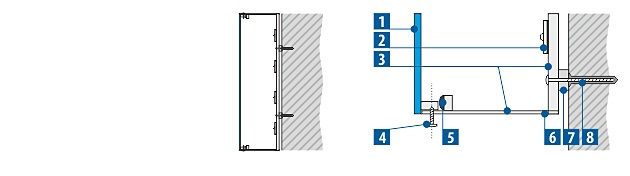

Lightbox of bonded PVC plastic. Illuminated only in front

1. Light distributing 3-4 mm acrylic panel

2. Light source

3. PVC base plate (10 mm)

4. Front panel mounting screws

5. Sealing gaskets

6. Draining hole

7. PVC plastic shoe (10 mm)

8. Screws (~4×70 mm)

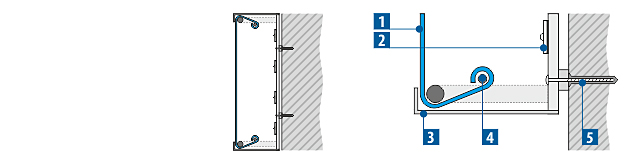

Lightbox with translucent PVC tarpaulin. Illuminated only in front

1. PVC tarpaulin fabric

2. Light source

3. Side finish (tin, aluminum composite)

4. Tarpaulin tensioning mechanism

5. Screws (~4×70 mm)

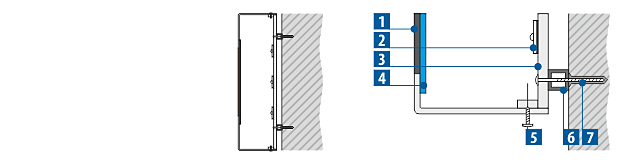

Housing – bent composite plate with milled through letters. Only letters illuminated

1. Hole (letters) milled in the composite panel

2. Light source

3. PVC base plate (10 mm)

4. Coloured acrylic panel attached from the inside

5. Front panel mounting screws

6. Metal profile (20×20)

7. Screws (~4×70 mm)

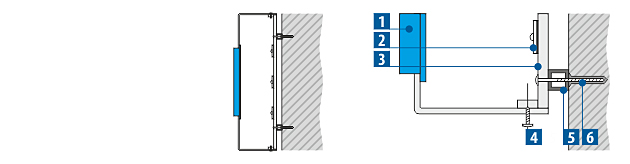

Acrylic letters, mounted in the milled housing of the composite panel. Only letters illuminated

1. 20 mm thick engraved letters from acrylic sheet, mounted on the inside of the hole which is drilled in the composite panel

2. Light source

3. PVC base plate (10 mm)

4. Front panel mounting screws

5. Metal profile (20×20)

6. Screws (~4×70 mm)

Lightbox installation techniques are further discussed in section Advertising installation.